Found

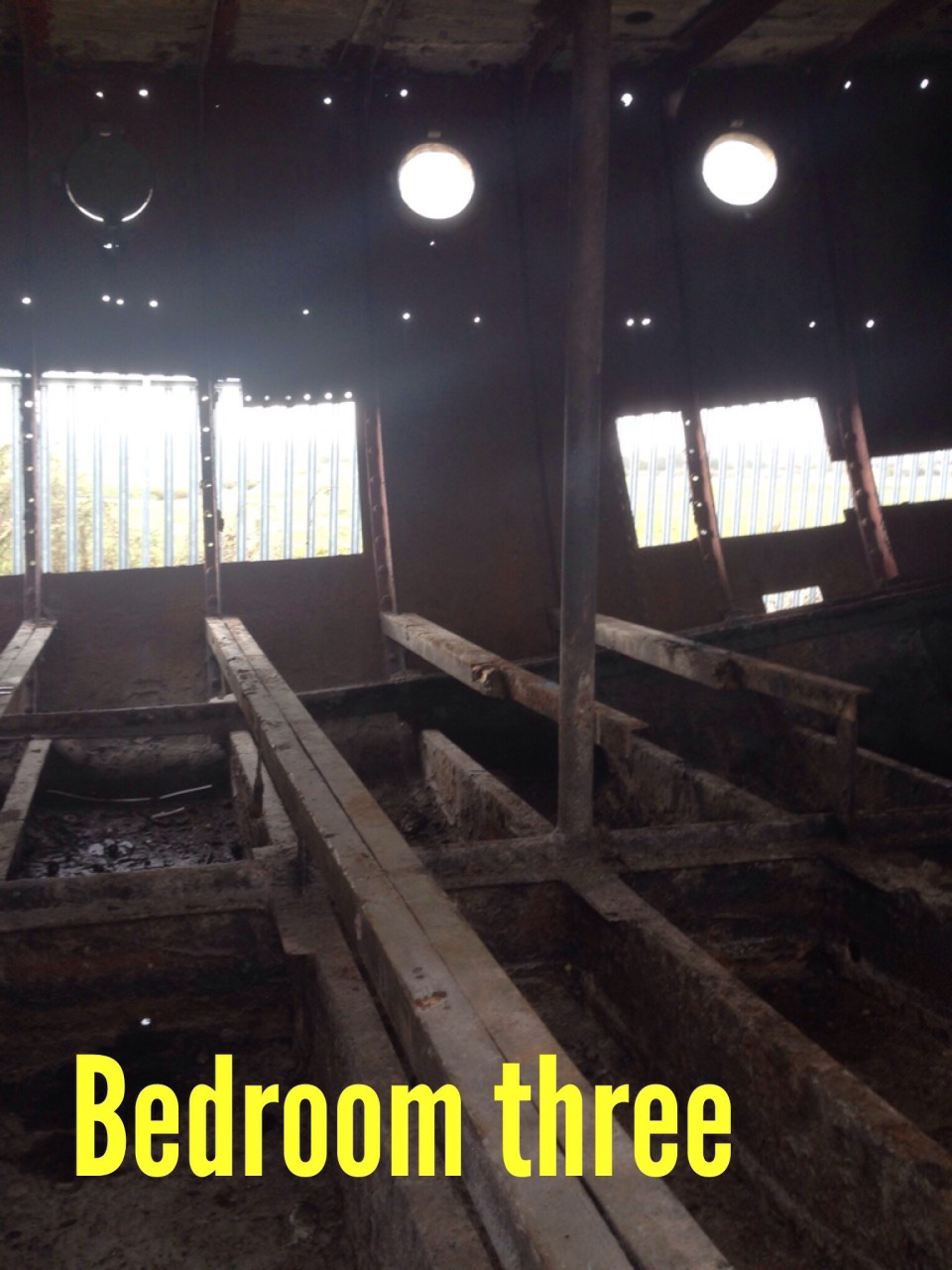

Floor plans

The current stage of renovations have advantages and disadvantages. The disadvantages mainly centre around the fact that there are more holes in the hull than hull making it unbelievably unseaworthy.

The advantage is that, with the ability to peer through the walls of the hull, the extent of the space is revealed. And turns out there is actually quite a lot of room down there.

You do have to do a bit of squinting and a fair bit of suspension of disbelief BUT I reckon when all done it won’t be shabby at all.

I was going to make a “through the keel-hole” / “through the keyhole” type gag here. But that would be lame…

Day 3: yet more holes

Day 3 and things are motoring along. The sides and back are done as are many of the smaller patches.

This lets the light flood into the hull.

One of the biggest transformations was cutting out the old diesel tank from the forward cabin. This was, from Toby’s account, a truly horrid job involving sitting in a tank of sludge while cutting the tank away. The efforts paid off and the space has really opened up.

Another transformation has happened at the very front where some very dodgy patches have been cut off.

And here’s the scrap.

Day 2: the sparks are flying

Day 1: It gets worse before it gets better

The welders arrived in force to start the cutting out.

First the strip along the waterline below the striker rail.

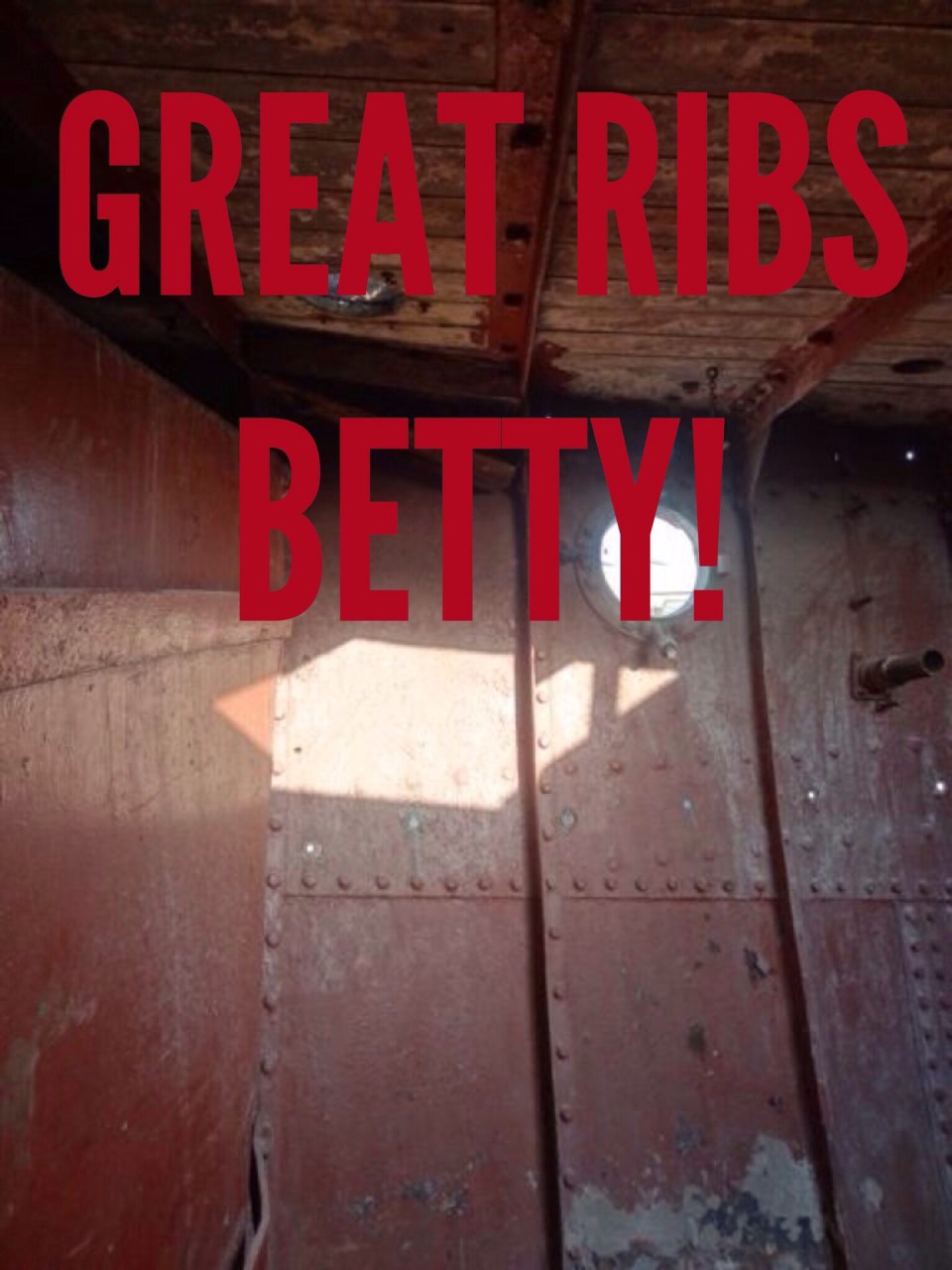

Then the section at the back was peeled back to reveal the ribs of the boat.

And the other side.

The metal was cut, pulled, grinded and levered out of the way. The heads of the rivets were cut and the metal gradually pulled back. With the ribs exposed she started to look quite animalistic, like a big rotting whale carcass.

Three more days of cutting to go. By Thursday will there be any boat left?

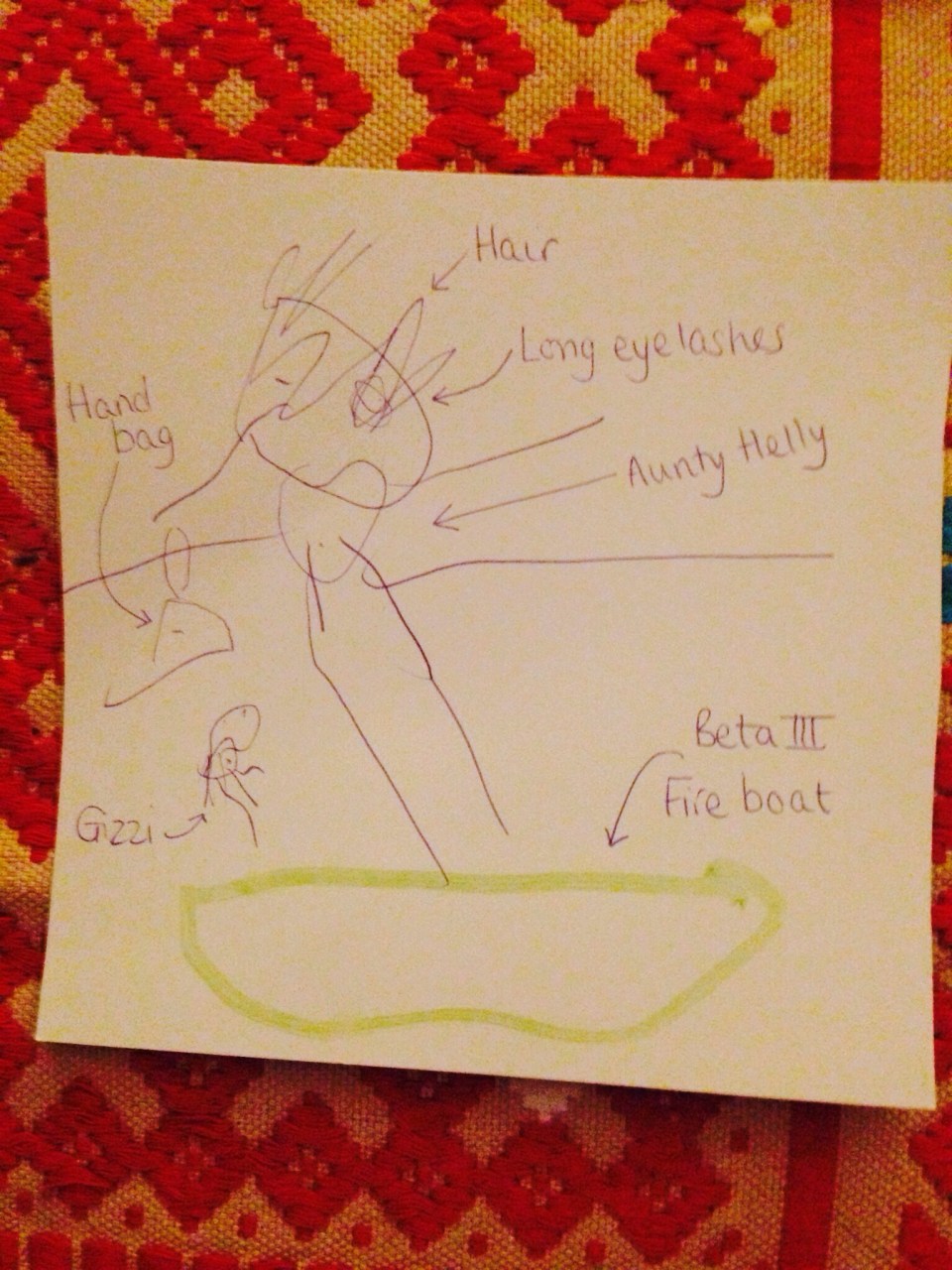

About sums me up

Bang on trend with the boiler suit

Things I have learned about welding

Much of yesterday was spent trying to follow the conversation between the welders and the surveyor about different techniques, approaches and potential solutions. In no particular order – and also probably also lacking some intelligibility – here is what I learned….

* You can cover a hole through either an INSERT or a DOUBLER

* An INSERT involves cutting the weak bits away and welding to the nearest thick bit of metal to lie flush with the existing surface

* A DOUBLER is essentially a patch which will be raised.

* INSERTS look NEATER, DOUBLERS can be QUICKER to execute but create a join that can be more prone to deterioration.

* lots of Dutch barges have a DOUBLER that covers the ENTIRE BOTTOM of the boat. (In my head I have equated a doubler with a big metal nappy….)

* doubling up the bottom can cause it to SAG as the new bottom structure isn’t attached integrally to the RIBS of the boat. You do not want a SAGGY BOTTOM. (Either in life or in the world of steel boats.)

* welding to a section that is RIVETED is not the ideal solution as rivets have a certain amount of give while welding is more RIGID. This can cause STRESS (as can metal boats).

All the errors in the above interpretation are my own and no reflection on Arc Fab Sussex.

I did try and clarify my interpretation by reference to “The Complete Guide to Metal Boats” (see previous review) but all it said was “why bother with the welding, its gonna sink anyway”.*

While sounding like the boat equivalent to “having a good rack”, this is very much a compliment. You gotta have good ribs.

I also learned an interesting bit of social history from Alex the riveter. That chick in the boiler suit and headscarf from WWII… Rosie the Riveter.

With her own incredibly catchy song.

* Disclaimer: for legal reasons, that was a JOKE