I mostly seem to time trips to Woodbridge with low tide when Beta III is firmly wedged in the mud. Not so this last trip. A mucb higher tide and looking great.

I mostly seem to time trips to Woodbridge with low tide when Beta III is firmly wedged in the mud. Not so this last trip. A mucb higher tide and looking great.

This is very big news indeed in the world of Beta III. Long long time readers will remember that the deck was originally painstakingly repaired and patched and caulked and sikaflex but it failed. It leaked a little at first, ignorably so. Then it leaked some more and more and more until it was often raining more inside the boat than out. Not ideal at all.

A leaky deck meant a lot of the hard work on the interior was trashed. Heartbreaking. But not really rectifiable as a lot of the problem was the condition of the teak – it was just a bit old and dry and past it to realistically be resealable. And the problem with leaks is it is often hard to trace where the water was coming in and what needed patching. While the quality of the wood meant it held a lot of moisture, particularly at lower points where it should have run off. Making it all worse.

Trying to salvage the deck again was clearly the route to madness and more of an exercise in futility than normally presented by this project. It came to the point that even i had to draw the line. So it had to come off, all of it. Gone.

And the good news was that this presented an opportunity to do things differently. With the 3 inch thick planks gone, we could do a proper ply subdeck (there was none previously) which would make it properly watertight and give a proper foundation. There would be teak but this would be more of a veneer, stuck and sikaflexed to the ply subdeck. In addition, the overall layout would be simpler… not bolting the planks down would mean no caps over the bolts that kept popping off. The unused repatched hatches could be removed, the divide in the main deck where it had been lowered and raised could go. A simpler layout and fewer seams and joins and superflous bits of deck furniture would also make for fewer chances for leaks.

And what a job. Matt and Jesse have knocked it out the park with the refit. The front deck was done two years ago and then last year and this year the rest was completed. Bar a a bit of snagging to some of the seams (hence the blue tape), it’s all done.

And it seems to have worked. Re-doing work is always gutting but i think this is the real opportunity for the boat the push forwards. The deck is now FINALLY (yes, 12 years later…) watertight. Should i have gone down this approach all along? Probably. Is hindsight a wonderful thjng? Absolutely. Lets not torture ourselves with this but just think of it as a great opportunity and a foundation for a restart. Onwards!

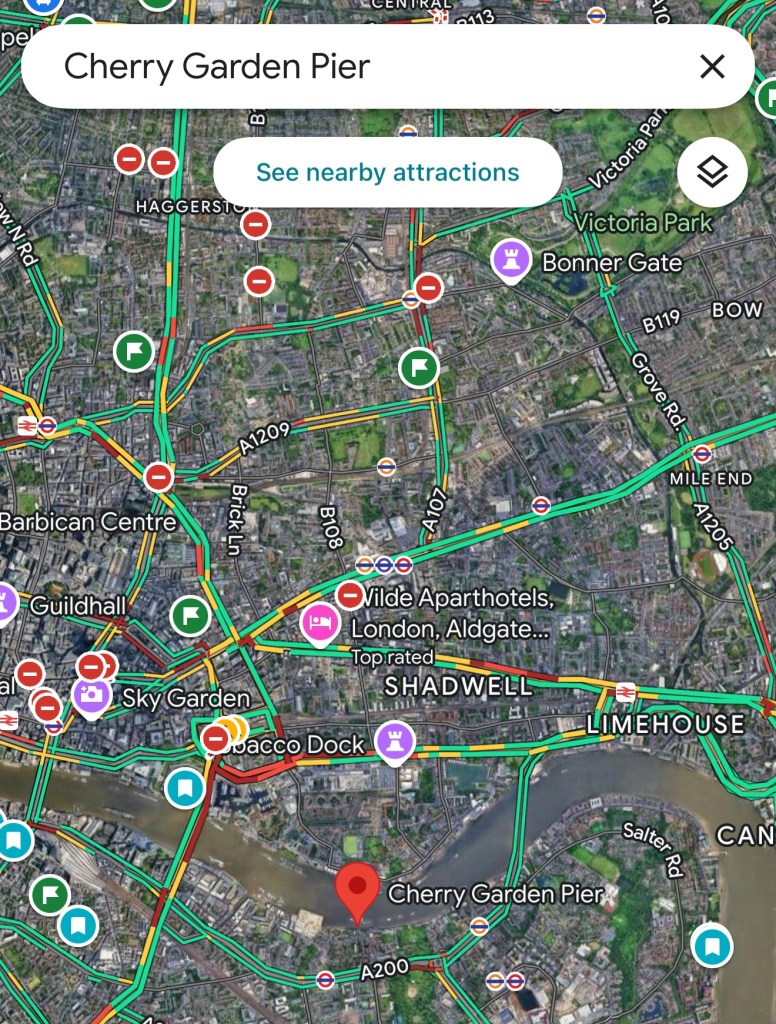

Beta III was stationed at Cherry Garden pier, north of Bermondsey just east of Tower Bridge on the south bank of the Thames. Ive whizzed up that stretch a fair few times on a Thames Clipper but always been looking out of the wrong window at the wrong time. Not so this trip…

And it is right smack bang next to Tower Bridge…

Which in turn explains this picture of Beta III…

And to anyone asking “who needs two model fireboats?”, i say let’s meet at the Woodbridge boating pond (yes, such a thing exists) and race!

Im still here and still plodding away on PROJECT BOAT. Time is – as ever – tight… that whole you-have-the-same-number-of-hours-in-the-day-as-beyonce just doesn’t hold true when you dont have an entourage. And, without pointing fingers, Beyonce has been kinda quiet recently too.

Work has been progressing – less me and more Matt at Woodbridge Boatyard. But more on that when we break for christmas.

In the meantime, Andy jumped on to the “get in touch” page to share a really cool anecdote. Very much a snapshot of a time and place in London history. Just imagine little Beta zipping over there with hoses at the ready.

Hi there, great to see the boat being restored to good use. I can’t help with the restoration but I do have a story. My 18 year old grandfather was on watch overnight on February 8th 1928 on the SS Trevilley at Greenwich buoys after a voyage from Argentina laden with sugar. Around 08:00 he noticed smoke from one of the holds. Now I don’t need to tell you that sugar and fire are not a good combination. Gratefully although two holds were aflame and there was much smoke and fumes three fireboats from Blackfriars, Rotherhide and Cherry Garden Pier quickly arrived to get the fire under control and extinguished by 09:15 with no injuries to anyone. The ship sank with all the water but was refloated, scraped and repaired within a few months. Based on the service dates of the Beta III I believe it was the fireboat that came to the rescue from Cherry Garden Pier that morning !

Good luck in your restoration !

Andy

Well… funny you should ask, as I’ve finally got an update. It’s been a year (A WHOLE YEAR!) and another baby since the last post and the whole boat strategy has changed. Gone is the DIY option and I have put the boat in the capable hands of Woodbridge Boatyard. Phase one and deck one is now complete.

They’ve come up trumps in working out how best to sort out the deck. To spin through the strategy… the original deck was all lifted, the beams replaced with ones that have the original camber so water flows off more freely, ply subdeck added and thinner layers glued down. The underlying theme to this approach is simplicity and, in deck terms, simplicity also means “less likely to leak”. We don’t have bolts and caps every foot along every plant, the deck furniture has been rationalised, and all the weird patchy bits are gone. It’s neater – and crucially- less likely to leak.

Doesn’t it look smart? The finish is oiled and it just looks so good. Now for the other two…. Next year. Work starts in spring. 2026 is the boat’s 100th birthday… effectively two years to get her shipshape (we will close over the fact it’s been almost 10 years since this whole thing started)… the challenge is on!

The plan…. the teak has been removed from the deck, alongside all the deck fittings. This has revealed some “somewhat Lacey” deck beams that want replacing and some rather ropey teak. The course of action is to add in the new deck beams but with more of a camber to the deck – this is how it would have been originally and allows the water to more readily run off the deck, hopefully avoiding it all rolling towards the windows and making that soggy. Then we are having a new marine ply sub deck, on top of that will be much thinner planks of iroko/teak (probably about an inch) which will be glued down the the subdeck.

This avoids a lot of the previous problems of every seam and every bolt and every patchworked area of deck – and there was a bolt about every foot of length and six inches across the beam – being a potential point for water to come in. There won’t be all the soggy cotton caulking wicking any water along the seams. And it will look just as good, if not better. I’m not a purist when it comes to this project… let’s make use of modern glues and methods and come up with the most practical, achievable solution that will mean we can actually use the boat. Simples, and if this doesn’t work I’ll just cover the whole bloody thing in tek-dek, okay?

So we don’t get too down about having to re-do the decks, let’s remind ourselves how far we’ve come…. A recap to some original Beta III imagery.

(WHAT WAS I THINKING…. HOW WAS THIS PROJECT A GOOD IDEA?!?!)

So why the updates all of a sudden? Well, at least that’s what my Dad has been asking… possibly my only follower here, certainly the one who is paying the most attention! Well the update is because some work is actually happening on Beta! Your jaw might hit the deck at this news, and that would be more than appropriate as it’s the deck that is being fixed.

The deck? Haven’t we been there before? Yup, yup we have. We spent a good summer or so raking out the seams, routering them, caulking them, priming and squeezing sikaflex (remember that ghastly stuff?) but…. All to no avail. It still bloody leaks. This has been fixed on the main deck with an additional cover but on the bow deck, it is still pretty drippy to the extent that it is stopping her being usable and damaging the inside.

There are many reasons why she still leaks. Let me list them…

1) it was an amateur effort in caulking and silaflexing. And while it really was best efforts, there are hundreds of metres of seams, sikaflex is not a forgiving material and one missealed join and lead to a problematic drip, likely a way away from the point of entry, just to confuse things further. I don’t think we could have done a better effort but the proof unfortunately is in the pudding and it leaks.

2) the condition of the teak. The wood is nearly 100 years old. While we’ve patched in a good amount, there are still pieces where it’s just too dry and cracked to be solid. We could try and cut out more sections and patch in more new wood, but….

3) that bow deck is a real mishmash patchwork or deck bolts, hatches, furniture and random pieces. All this means more joints and more chances to leak.

4) what it was built for then, and what we want to use it for now. As a working fireboat the emphasis was on a solid deck, all 3 inches of it. It didn’t matter if there was the occasional drip down into the boat. But when you might be sleeping on it and don’t want the floating garage look on the interior, it very much does. Different priorities.

Time to get the professionals in. We (and by we, I mean Tam) floated her down the river to the Woodbridge Boat Yard. If you haven’t had a look in their workshop which is open to the quay, you really need to. It’s a treat. They have taken a look and we have come to the conclusion that to try and rake the seams and re-caulk in its current state would be throwing good money after bad. All that work could be done and there would be no guarantees that water wouldn’t be getting in elsewhere and we’d be no further on. Not idea.

More on the plan in the next post.