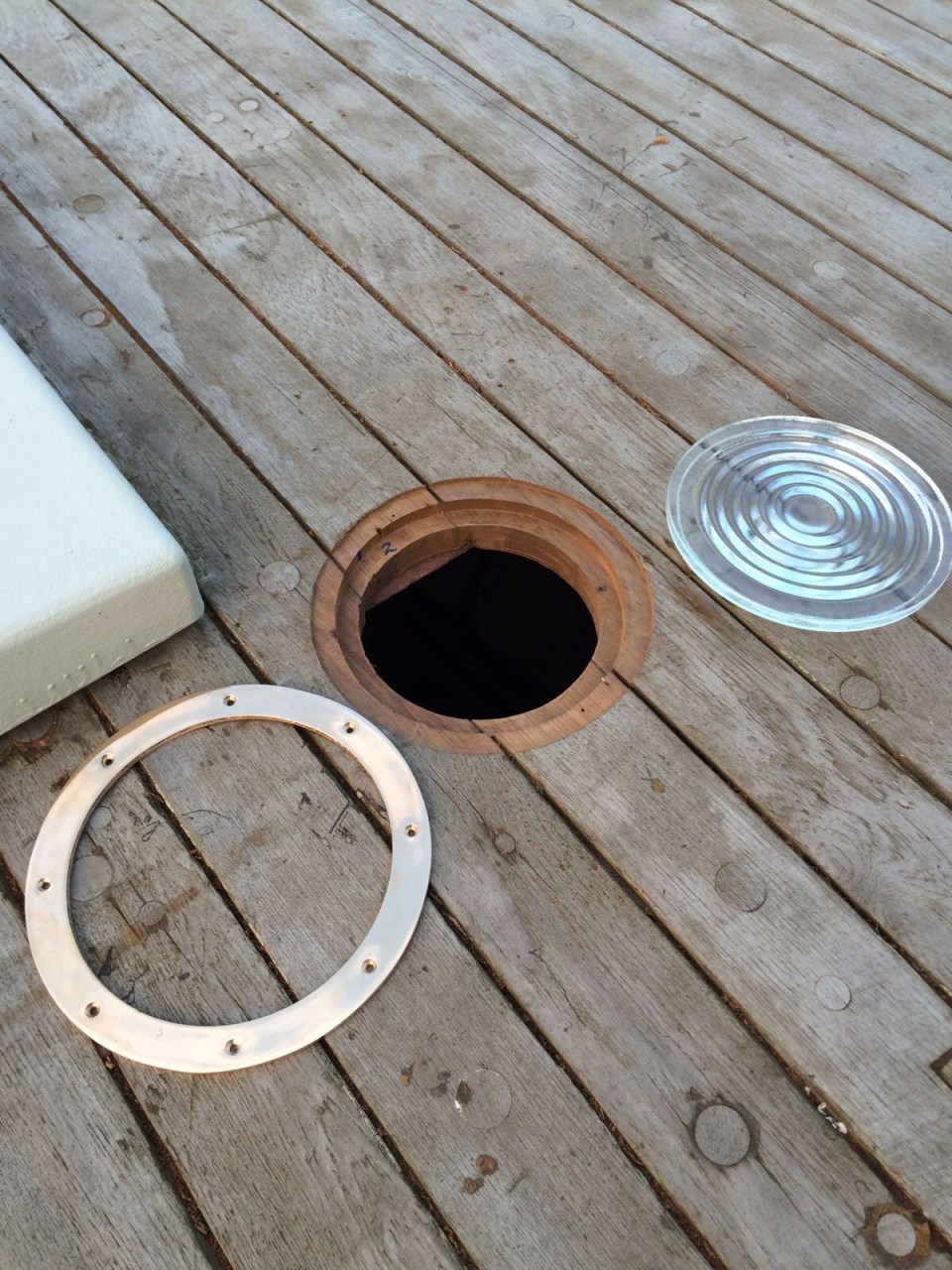

The deck is in pretty good shape but, where hatches and vents have been moved and where the pumps originally stood, there are some gaps and crappy inserts. Given many of these are circular, it seemed like a good idea to sink some circular deck lights in there. I grabbed some from Davey & co and Ian showed me how they are put in…

First they were put roughly in position.

Ian then rigged up a template that would allow exactly the right shape to be cut in the deck. The glass needed to be set into the deck so it sits on a recessed step. Then the brass ring sits on top to secure it in place. To get the dimensions right, Ian knocked up a rig to ensure the router was cutting the right shape to the right depth.

Then best to test it out on some spare bits of random wood rather than jumping in and trying it straight out on the deck. Slowly slowly catchy monkey.

With a couple of adjustments, it’s on to the deck.

And they’re in and looking fabulous. These will be fitted for good once the deck has been caulked and sanded as the seams want to run under the decklight. There will also likely be some bedding compounds and such involved to get them shipshape and water tight.

It’s starting to come together!!!