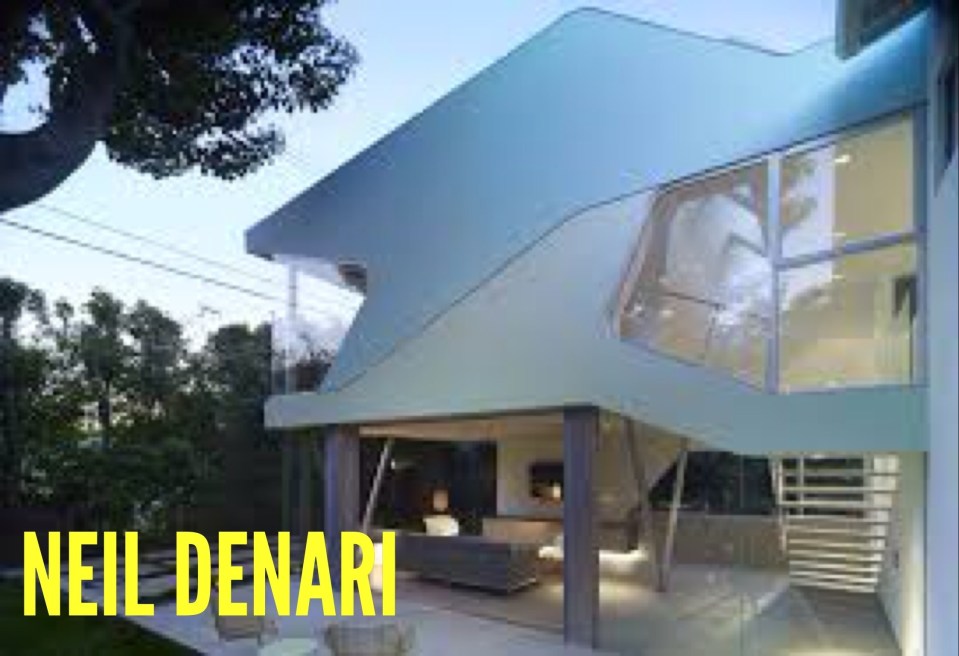

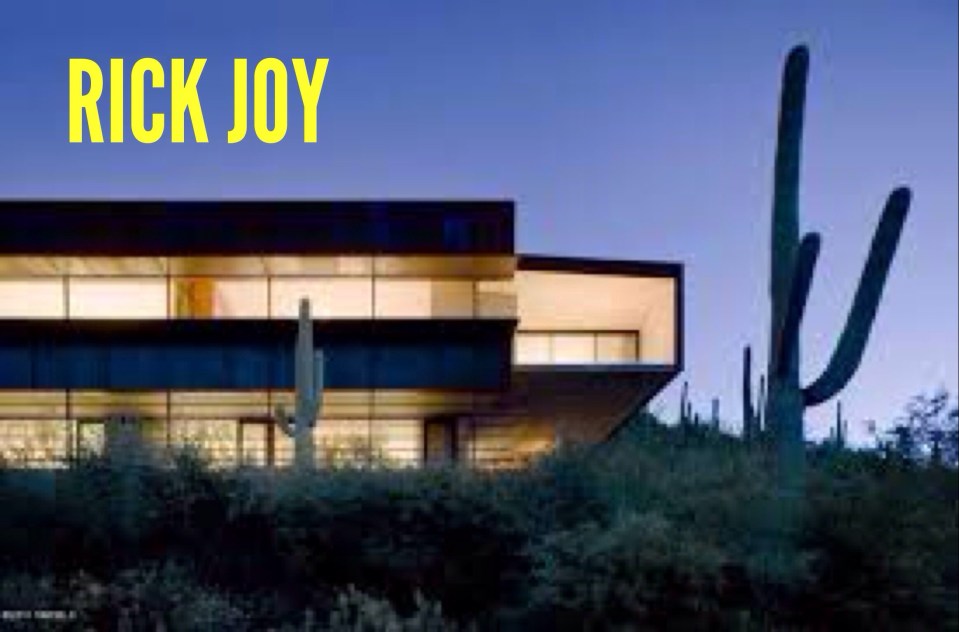

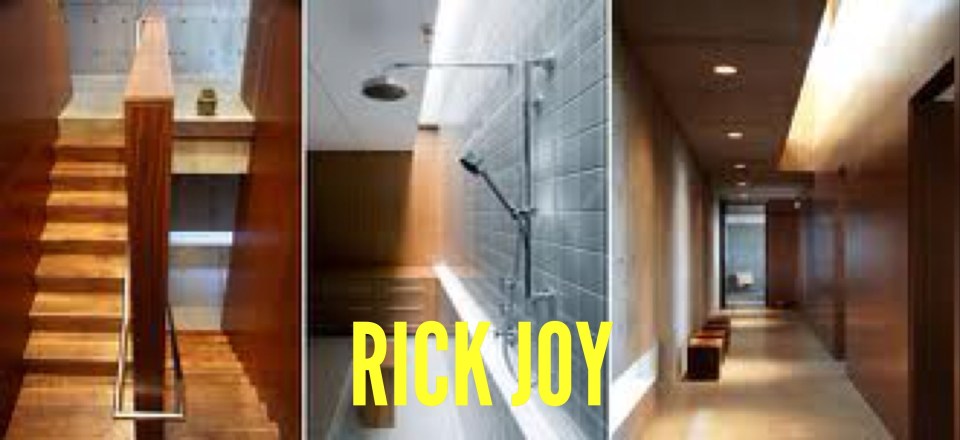

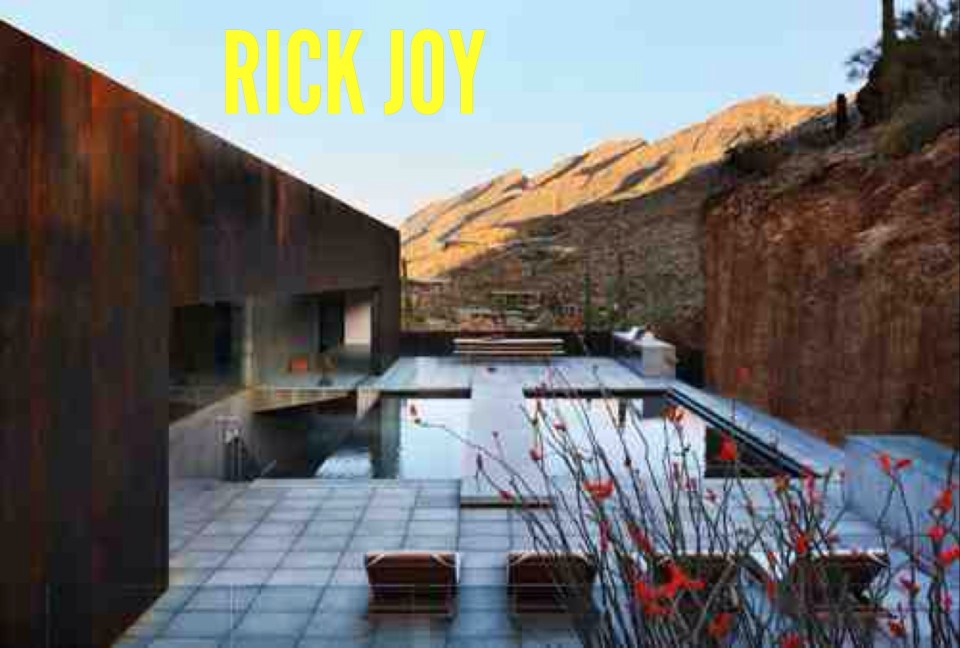

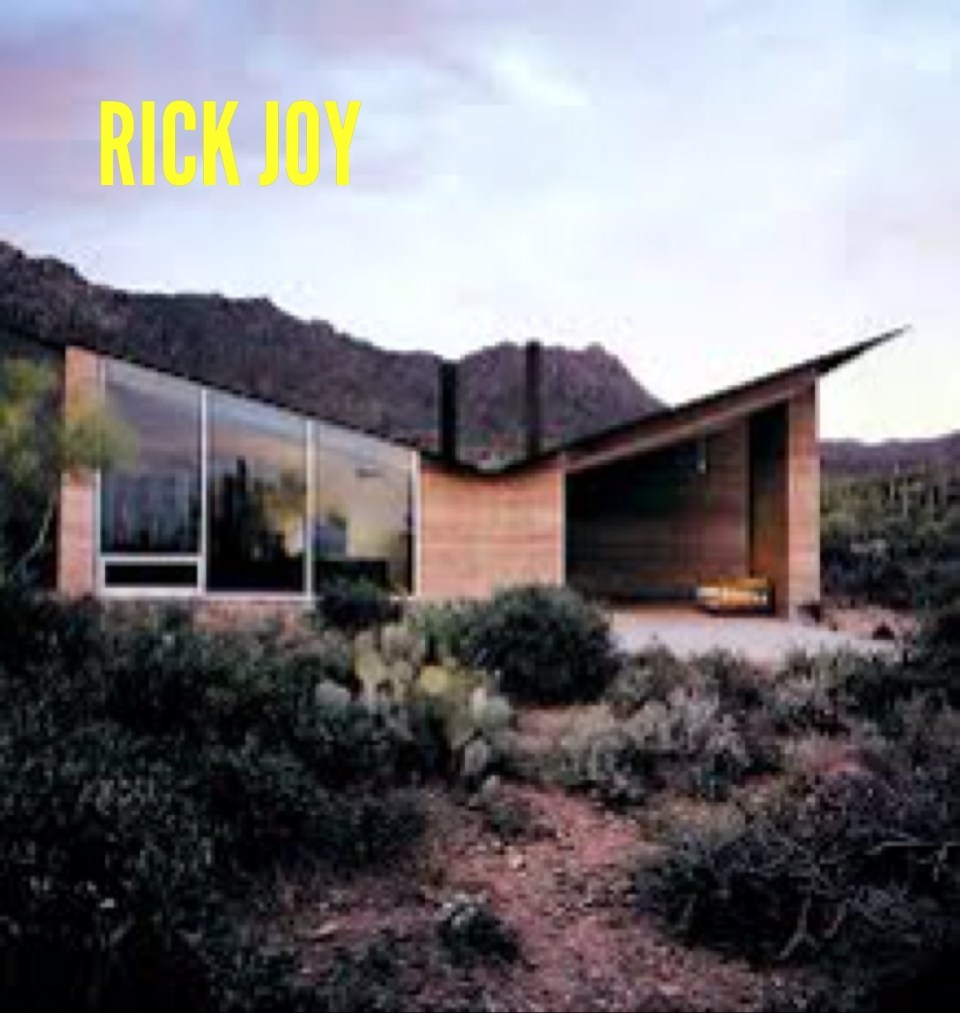

Neil the architect has been in touch with some more potential sources of inspiration for the top structure. Namely, Lot-ek, Neil Denari and Rick Joy. I have posted some of my favourite designs below. Lots of steel and glass alongside some wood. Rick Joy was my standout favourite although it remains to be seen whether the structures have the same impact when the big blue desert skies are replaced by a sky full of grey English clouds.

I think you can probably see a theme developing here. One final aside… As much as I love these glass, boxy designs there is one thing that troubles me… Not overheating, direct sunlight or warmth in winter. But BIRD SHIT. They look fantastic, but what happens when a flock of pigeons or seagulls do a fly-by dirty protest, inevitably on an impossible to reach part of the structure?