When not welding, jack likes to do a bit of doodling!

Girl power

Today’s efforts…

Breakthrough

Literally. But this time the welders haven’t been welding but rather cutting away. Specifically through from the rear cabin into the engine room, the engine room to the main cabin, and the main cabin to the front cabin. The new openings have been framed like doorways and the space is really starting to make sense.

A tour… The view from the engine room looking towards the stern. You can see the doorway leading into the front cabin.

The view back into the engine room showing the corridor down the side and the newly framed hatch on the deck.

Looking back into the rear cabin.

Neil on the phone – this shows the height in the main cabin as he is about six foot.

Looking from the front cabin back to the main cabin. The headroom is a bit restricted in here so it will be a sleeping area. Big enough fora double bed though.

The hatch you can see above in the front cabin will be framed and have reinforced glass. You can lie in bed and stair at the stars.

Next steps

This week was a sure meeting to discuss the odds and ends that need tying up to finish the structure, seal the boat up and make sure there are no odd sticking out bits of metal or tetanus hazards…

Now the boat is mostly watertight bottom up, the next objective of to make the boat watertight top down. This means putting in a frame around the hole in the deck where the engine was lifted out and putting windows in the front raised section. This will keep the rain and sand out and mean that work can start on painting and prepping the inside.

One job is finishing off the engine cooling system in the floor of the boat. This takes the engine to bring a closed system which reduces the maintenance and means fewer holes in the hull of the boat (always a winner).

The picture below shows Alex the welder standing in the main cabin. Any photo of this space with someone in it really shows off the height of the space.

And the massive engine cooling system between the ribs. Hopefully this can also be used as underfloor heating… Jury is out in this but it could be a possibility?

Sun’s out

A striped finish perhaps?

The latest

Spring has sprung in Rye and work on the boat has sped up!

I have been prepping the decks ready for the carpenters. This has involved pulling out random rusty nails and scraping out the old tar and sand and gunk from the seams. Once again work on the boat involves scraping and shovelling shit.  They still look a bit dodge but up close they are much better, believe me. I do need some of those knee pad thingies though. The margin planks will be fitted next week, more on that later…

They still look a bit dodge but up close they are much better, believe me. I do need some of those knee pad thingies though. The margin planks will be fitted next week, more on that later…

Underneath the boat, the welders are finishing up and are fitting the engine cooling system. Plan is to have a closed system and for the water to cool by running through this maze of pipes. Question is, can it double as underfloor heating too?!?

More updates to come as, with the improved weather, hopefully progress will speed up.

An ode to shot blasting

If the state of the hull weren’t proof enough that shot blasting is pretty amazing, this experiment on the deck furniture definitely showcases it.

The rusty engine blocks sitting next to the good as new clean ones…

Similar bits of deck furniture pre and post blasting. As good as new!

And even some spangly bronze ones!

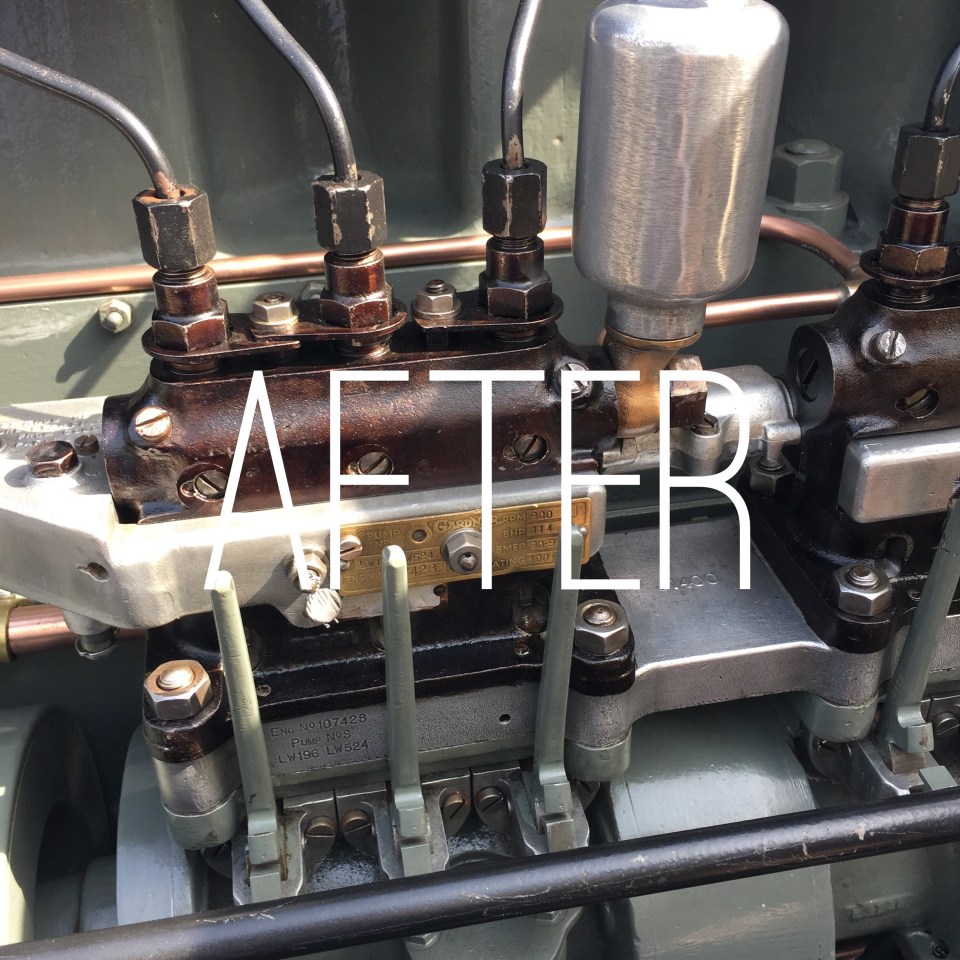

Before and after

When it seems like progress is slow, I am finding it useful and motivating to look back at the different stages of work and how Beta III used to look. As I have years worth of photos stashed on my iPhone, this is an easy process.

Here is a round up of some before and after shots which show quite how far we have come. Without getting into acceptance speech territory, a big thank you to all involved for their hard work, support and encouragement so far. It is starting to look like I’m not that crazy after all! 😝

The before…

And the after… (Or perhaps, more accurately, “work in progress”)