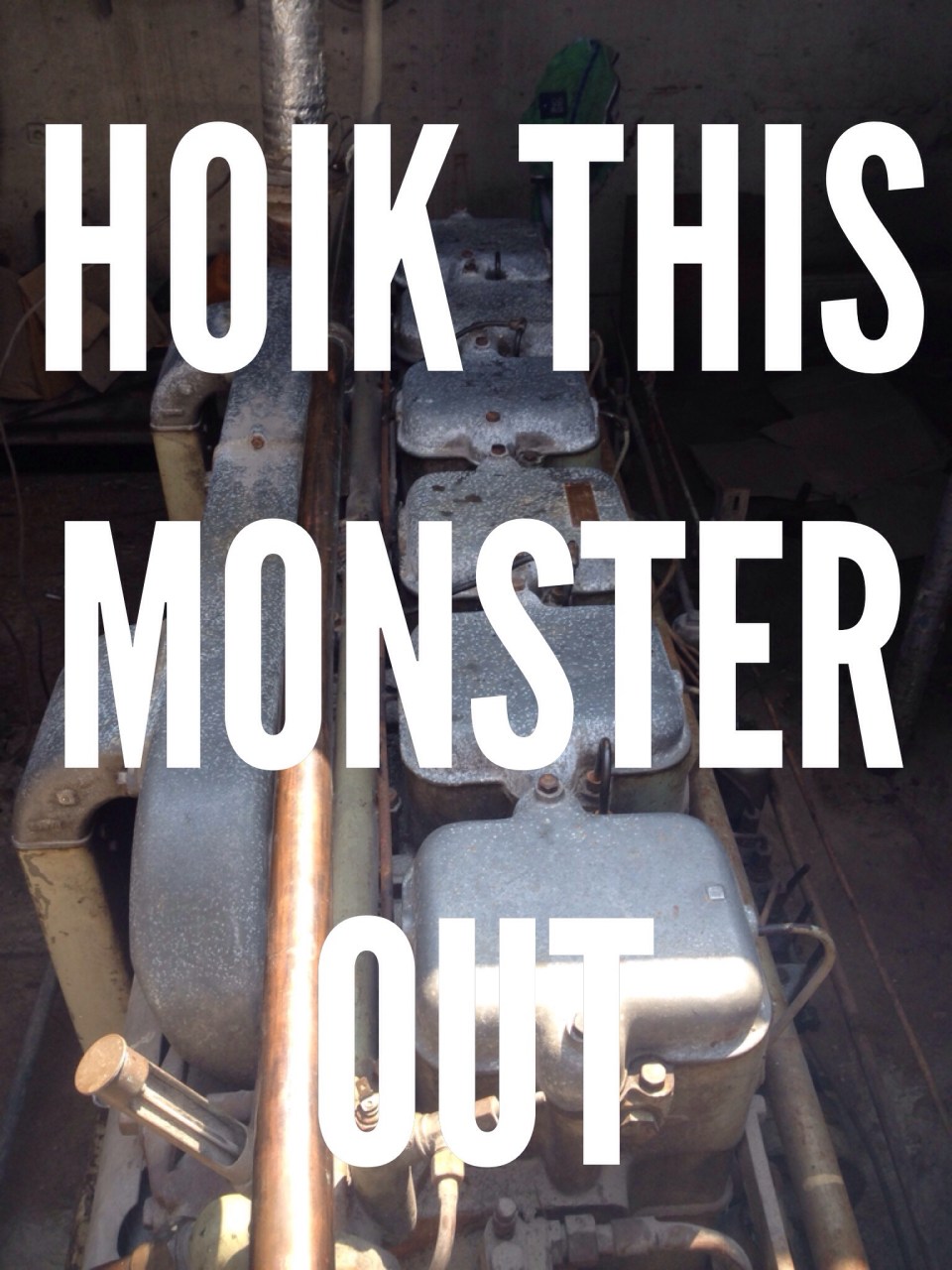

Sunday’s job was to get the bolts off the engine. Sounds like an easy job but these bolts haven’t been undone likely since the engine was put in in the 1950s and all the sizes for the bolts and nuts are imperial – whitworth to be precise – so won’t fit most tools.

Fortunately I had a VERY MANLY assistant in tow who was able to use a bit of ingenuity and a lot of elbow grease to get most of them off. **cue big rounds of applause, whooping and swooning** Unfortunately no photos of the bolts or the work in action as hands too covered in grease and grime to operate the iPhone.

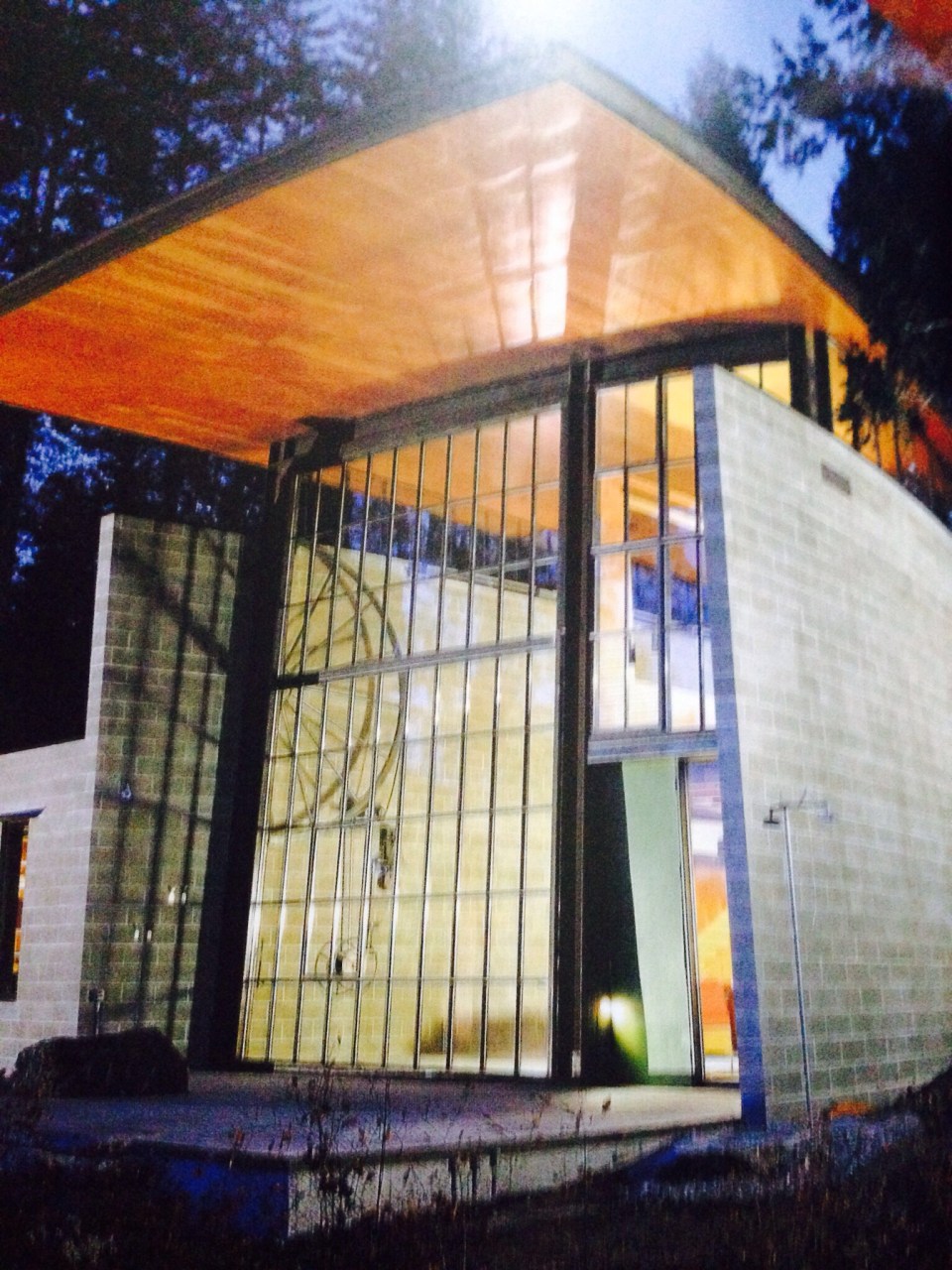

The reward was a quick drive down towards Dungeness. It feels like the end of the earth and is likely nearer France than London. The view one way was this…

The view in the other direction was this…

But best of all, you can get your gnashers round this…

(Excuse the teeth marks)

Best lobster roll EVER from my new favourite place, Dungeness Fish Hut.