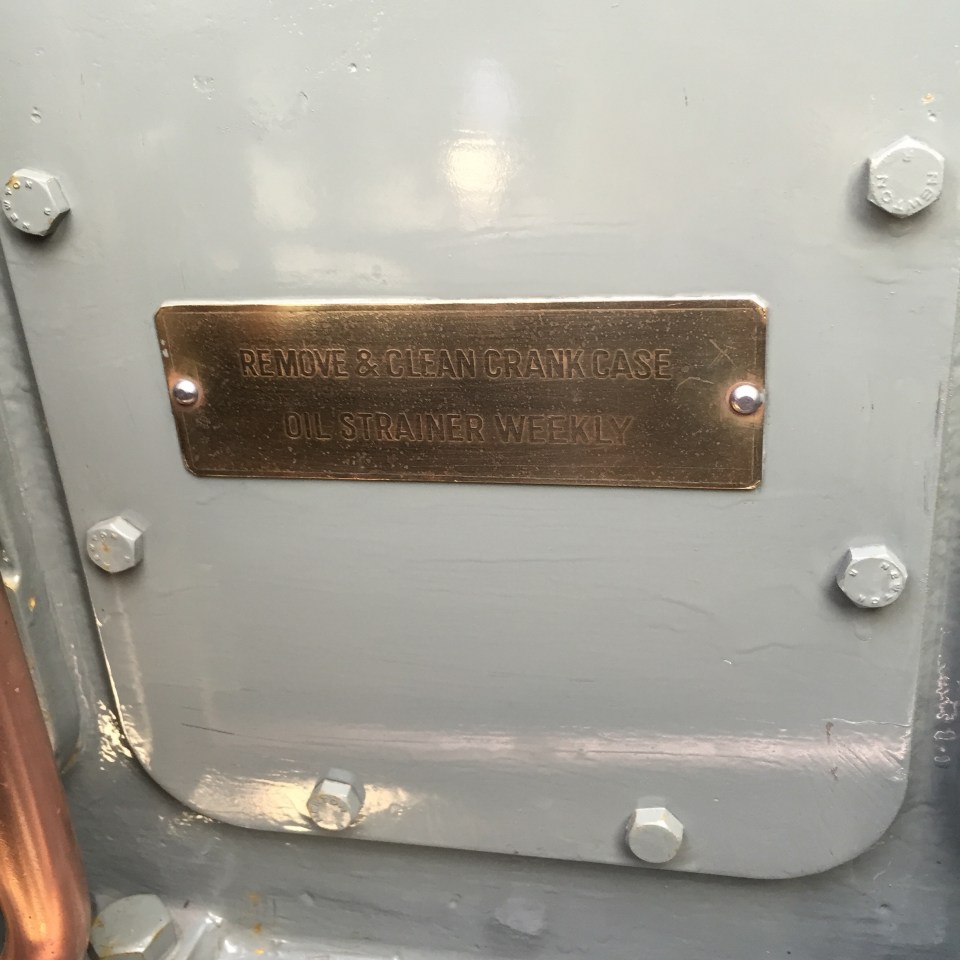

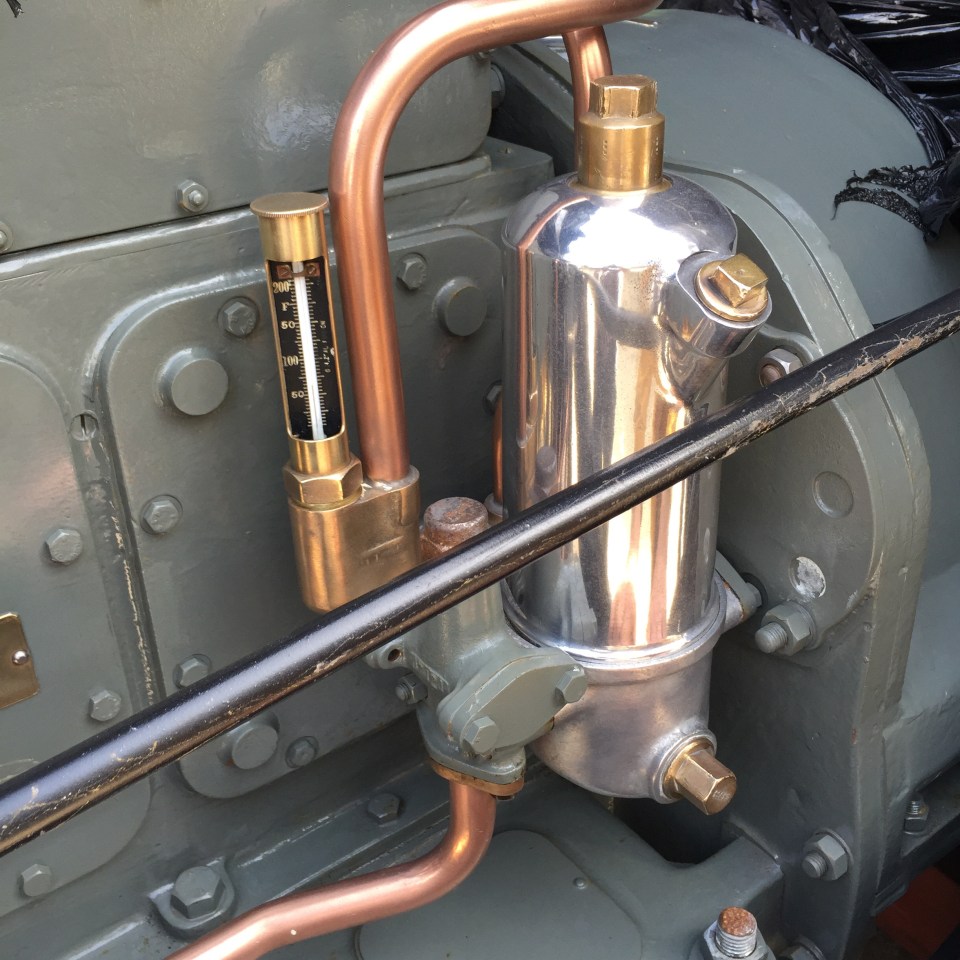

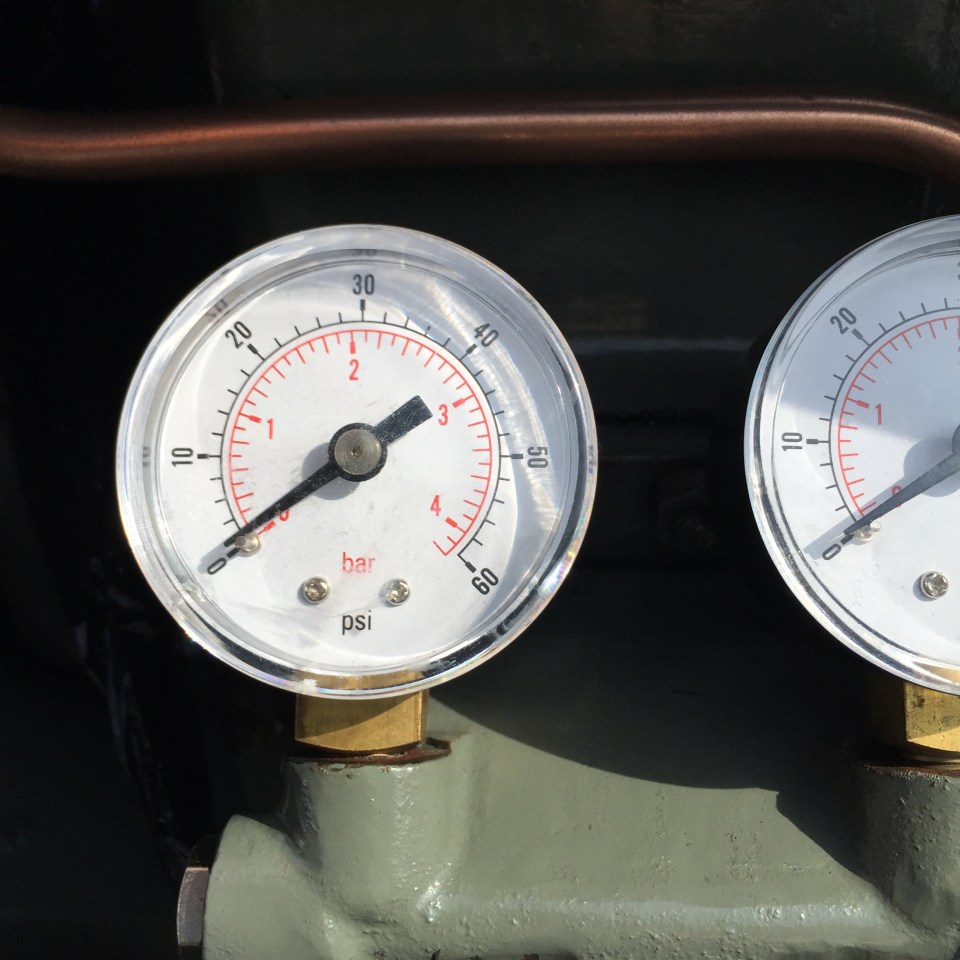

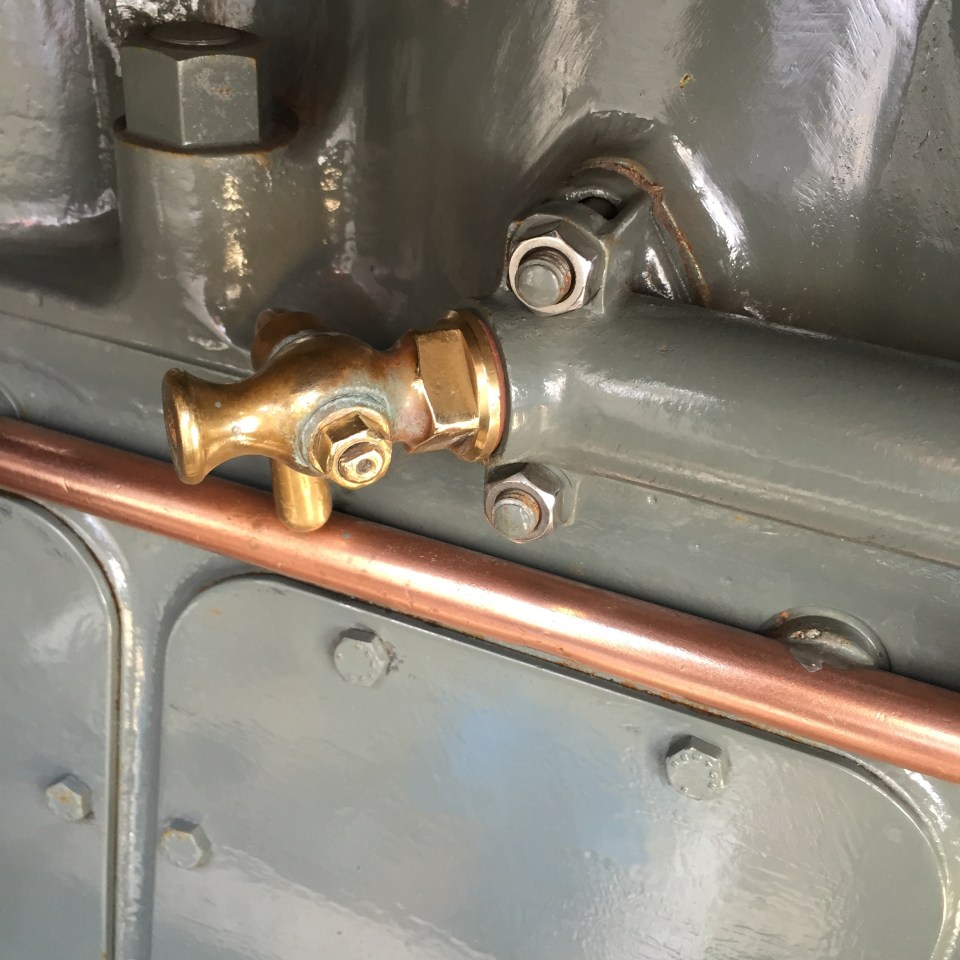

Some motivational pictures of how Beta III used to look…

Evicted

Bit of a high drama title. Truth be told the ever so patient owners of the site where we are based have suggested that they might need our corner back for their business and that this would need to happen at the end of September. They have been beyond patient and charming, particularly given they inherited us when they bought the site from the previous owner.”you know your new industrial site… there’s a mad woman and a rusty boat in the corner that can’t be moved….”. Exactly.

They have kindly suggested that we can always move the boat down a bit. It given that involves extra cost, the project has already dragged on, and we are nearly done, it makes sense to speed things up and get the job done. It’s a boat after all. It should be in the water.

My ha fa are a bit tied with the littlest crew member which makes things a bit tricky. If there is anyone out there who fancies a bit of hard labour and can help, please do!! I need it.

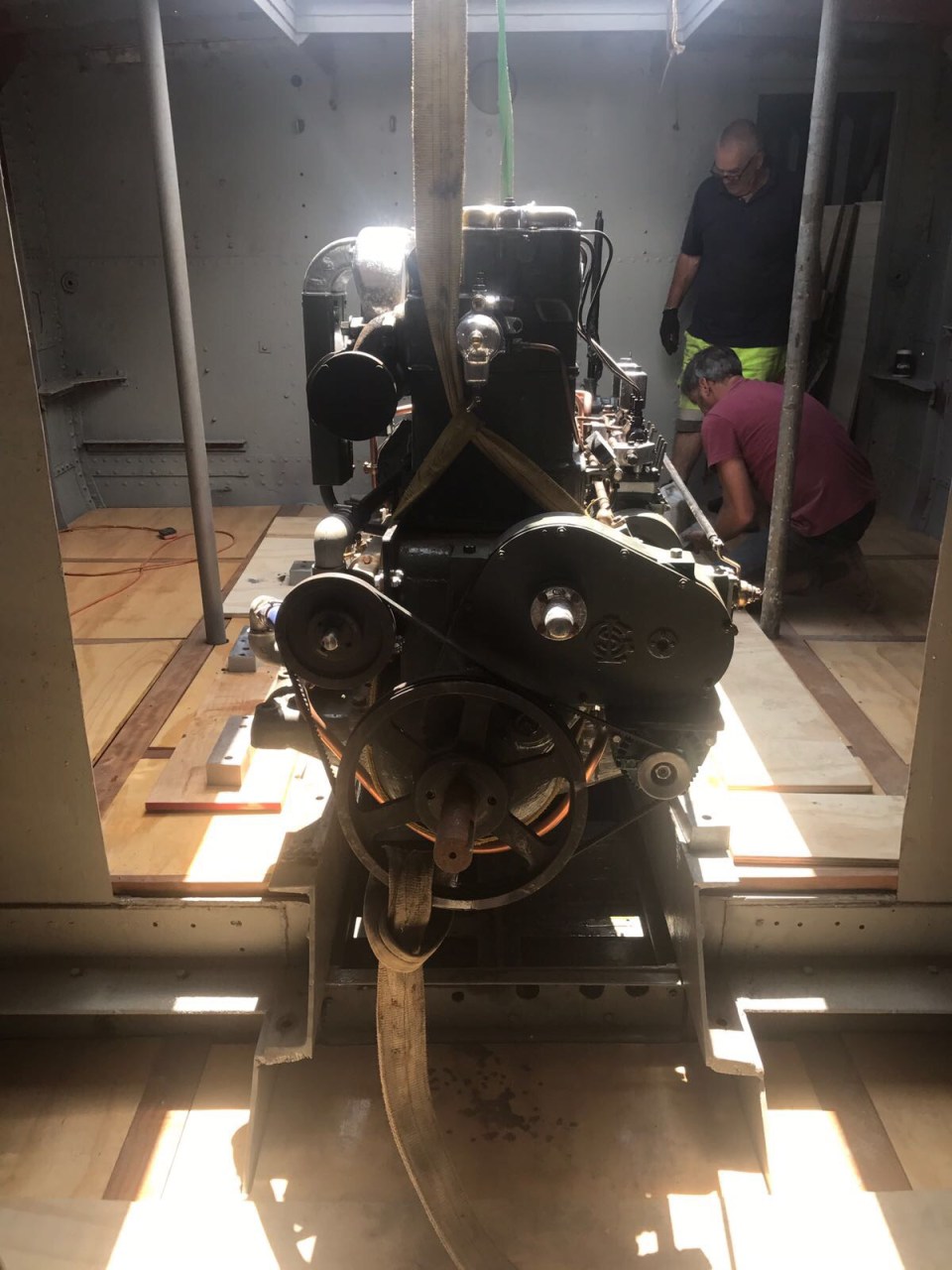

Engine in situ

Well thank fuck for that. I make no apologies for language, it was a high stress moment. It is in Place and just requires a bit of final adjustment and fitting and of course all the inputs and outputs hooking up…. another mammoth job but baby steps, right? It might not work yet but it sure looks good.

And in it went….

They are big old beasts these Gardner engines but, as the theory goes, what comes out must go back in. Or is it what goes in must come out? Either way, despite the fact we had made the engine hatch smaller (oooops forgot about that), the engine had to go back in abc in it went with some HIAB magic.’

They are big old beasts these Gardner engines but, as the theory goes, what comes out must go back in. Or is it what goes in must come out? Either way, despite the fact we had made the engine hatch smaller (oooops forgot about that), the engine had to go back in abc in it went with some HIAB magic.’

The smaller hatch meant it needed to go in at more of an angle so required some extra hair pulling and panicking from Tom (who was masterminding the move) and a block and tackle to provide a bit more support.

We have lift in

This Friday: a HIAB has been hired, the engine beds prepared, and my nerves steadied. It’s time to lift the engine back in!!!! 👌🏼👏🏻👍🏼💪🏼

This Friday: a HIAB has been hired, the engine beds prepared, and my nerves steadied. It’s time to lift the engine back in!!!! 👌🏼👏🏻👍🏼💪🏼

You get the idea. There is – as ever – a lot to go wrong… getting it out the shipping container, lifting it and dropping it back in the boat without smashing it into the deck. And god only knows where the mounting blocks and the bolts have gone… 😬 also have to make sure there are no crushed feet, people or boats and we get it the right way round. On the plus side, what came out surely must go back in, and at least we know it fits!

Step on it

Engine room floor

Next phase – the walls

Floor. Tick. Now on to the walls…

Great diagram huh? What this is trying to show is that there is a ledge half way up the walls above the waterline. This is about shoulder height and will be where a shelf sits. Below it there will be horizontal panelling built out from the ribs. Behind this I can put pieces of foam insulation (no spray on here!). The shelf can also conceal any wiring. In an ideal world (really not achievable when it comes to anything boat related) it would be floor to ceiling but this creates a big issue with the portholes and they would have to be built round (fiddly and crap looking) or put on a collar (not original and probably impossible to find the right fitting). The insulation will at least come above the waterline and should look good.

This is the first panelling sample. Called bead and butt apparently. Once that is painted (white I reckon, though could be persuaded to a grey) we really will be going great guns.

Turning point

There have been some major turning points in this project (bear with me as it has been a long project and hence lots of lots of turning points) that have spurred me on with the project and seemed like a real watershed moment. They include: getting the blimmin thing out the water in the first place, finishing the blasting, getting the first coat of paint on, finishing the deck, and now the floor. It’s down and looking truly truly sublime. I am yet to walk on it personally (child care issues etc) by I am assured that it is the soundest, smoothest floor you ever did step on.

The final piece to the puzzle has been the flooring round the engine. This ties in really well with the main cabin flooring and means the engine can just be dropped in place.

No mean feat with lots of fiddly bits round the edges and different levels.

This week’s update

The sun is shining and the wind blowing and all is progressing nicely with the good ship Beta III. We are motoring ahead with the floor. And by “we”, I mean Ian the carpenter. The beam sections that the ply boards sit in are in three main section. The central section is done – a straight run. Making it easier to complete the two side sections as there is actually something flat to work on.

The sun is shining and the wind blowing and all is progressing nicely with the good ship Beta III. We are motoring ahead with the floor. And by “we”, I mean Ian the carpenter. The beam sections that the ply boards sit in are in three main section. The central section is done – a straight run. Making it easier to complete the two side sections as there is actually something flat to work on.

Ian has bookmatched all the ply so that the grain runs from one piece to another and it all looks proper lovely. We don’t have a picture of this as it was all covered up. Will show you later.

I can’t tell you what a MASSIVE MASSIVE transformation it is to actually have a floor. The number of times I have twisted my ankle, or cracked it against the metal, or stepped into a puddle of water. This won’t happen again. Rather than hopping from beam to beam (usually with a big bucket of crud from the bilge) I can literally skip across the floor of the boat. This my friends represents significant progress.

Meanwhile in the galley…. for some reason we had missed Shotblasting the underside of the deck here so needed to knock off the flakey paint with a heat gun and wire brush.

This was manfully done by Tom. It’s a pretty awful job as it basically involves standing with your arms above your head for hours while flakes of paint rain down on you. The metal beams are all prepped and now being painted. The underside of the deck is a bit patchy as it isn’t possible to get it back to plain wood without sandblasting it. It may be that we end up painting it again which would bring some more light into the galley which is definitely the darkest room by some way.

Next up are those pesky square windows. Not found some brass ones in three years of searching so time for Ian to make a wooden version.

Tom has discoverer the joys of jotamastic…